REVit® Technology

Mitigate stick-slip and maximize drilling efficiency with the REVit® technology family

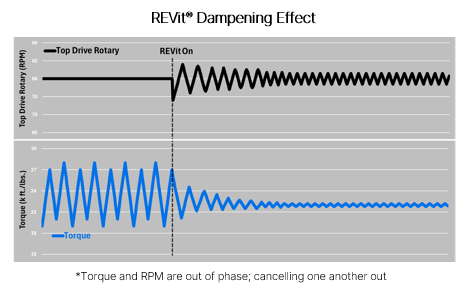

The Nabors REVit® technology family delivers advanced top drive automation that eliminates stick-slip, a common drilling dysfunction that limits drilling performance. REVit® helps extend bit runs, avoid unplanned trips due to bit and BHA damage, and optimize parameters for higher rates of penetration – resulting in significant drilling time and cost savings.

Within the REVit® technology family are two mitigation algorithms – single and multi-frequency dampening – to ensure that damaging stick-slip is always effectively mitigated.

REVit® ZT – advanced, automated stick-slip mitigation

Modern drilling operations push parameters and depth to their limits to maximize well performance. These operations require a new approach to overcome stick-slip.

REVit® ZT provides fully-automated stick-slip mitigation over a wider range of parameters and depths to ensure that performance rotary drilling is never stopped by dysfunction.

REVit® Technology Family Features

- Implementation of industry-standard Z-torque technology

- Integrated into the SmartROS® rig operating system

- Available on many 3rd party rigs with SmartROS®

- Full system automation

- Condition monitoring and support provided by Rigline™ 24/7

REVit® Technology Family Benefits

- Significantly reduce or eliminate effects of damaging stick-slip while rotary drilling

- Reduces bit damage for higher interval ROP

- Enables use of more aggressive PDC bits

- Enables optimized WOB and RPM for more efficient drilling

- Reduces vibration-induced damage to BHA and downhole equipment

Drill Smarter with Nabors

Tell us more about your needs by completing the form below and a Nabors representative will contact you soon.

"*" indicates required fields